|

The Gear making technique is now available as an instant

download ebook by clicking the button below this text. By clicking this button, you will be taken to Paypal to confirm.

You will then be sent instructions to download the files. If you do not have a Paypal account you can still use

a credit card for the purchase through Paypal. If you do not have or want to use a credit card I will also accept money

orders - email me for mailing address. The price for the technique is $29.99. The technique is on sale for $24.99.

|

How To Make Helix Forms On Your Scroll Saw. Added 3/9/2010 $24.99

|

|

|

|

Generating Gears In Wood (Updated 1/6/2010) $24.99

|

|

|

|

Wood Shells - A New Art Form $29.99

|

|

|

|

View items in your cart.

|

|

|

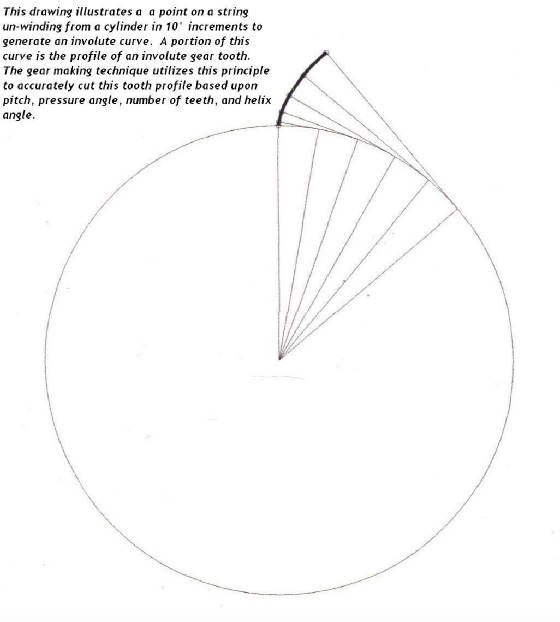

How Does It Work? The

technique utilizes a simple principle illustrated below to cut gear teeth rather than sawing or sanding to a line on a paper

pattern using the old method. This makes the task of cutting gears much easier, less tiring, and more accurate than

other methods, it also lets you make helical gears which are not possible with the old method. You can make gears with

any number of teeth . Chances are that you already have all the tools you will need: drill press, benchtop disc sander,

and either a tablesaw, scrollsaw, or table-mounted router (spur gears only with router). You can use ordinary off-the-shelf

saw blades or straight router bits. Personally I prefer to use a 24-tooth rip blade on my tablesaw to make gears with.

The simplicity of the technique is what makes it work so good. This technique when used with a table saw also gives

you the ability to re-work involute gears already made with other methods to correct any errors to the profile to eliminate

binding without having to start over or resort to laborious sanding. The only sanding you will need to do is to lightly

de-burr the edges after the teeth are cut or shaved to perfection. You will get a perfect profile even if your vision

is not very good because the cut does not rely on cutting to a line visually, the profile is generated as shown in the drawing

below.

| String Unwinding From Circle (Click To Enlarge) |

|

| Click To Enlarge |

Here are some samples of wooden gears you can

make using my technique. I have kept this to myself for a few years while learning more about it, but decided to sell the

technique as an ebook to educate others on how to do this and make some extra money. The technique enables you to make any

of the gears shown in these videos and pictures by using either a scrollsaw, router table, or a tablesaw. You can make spur

or helical gears with ease. If you purchase the technique, I will include an Excel spreadsheet calculator that calculates

all the needed dimensions using these input parameters: number of teeth, diametral pitch, pressure angle, and helix angle

if you want helical gears. I will also include a guide for elliptical gears as seen in the video. You will also get

future updates at no charge as I make improvements and add new capabilities, technical support, and sample guides (pdf format).

This is

much different than carefully sawing around a printed and glued on pattern. The correct involute profile is automatically

generated. This technique is very intuitive once you see how it works. There is no need for expensive cnc routers or lasers

or any computer-controlled tools. If you have a scrollsaw or tablesaw, the ability to cut accurately sized circles from plywood,

and a computer - then you can do this. You won't find this technique anywhere else, I have looked thoroughly and know

it is my own original idea.

Follow me on Twitter - my user name is steveg769.

Here are a few typical comments I get from customers:

Steve Wanted to thank you for enlightening me with your gear creating system. Without your system my

sculpture #22 would not have been possible. Here is a link to my site where you can see the gears in action.

www.stevenfleury.com

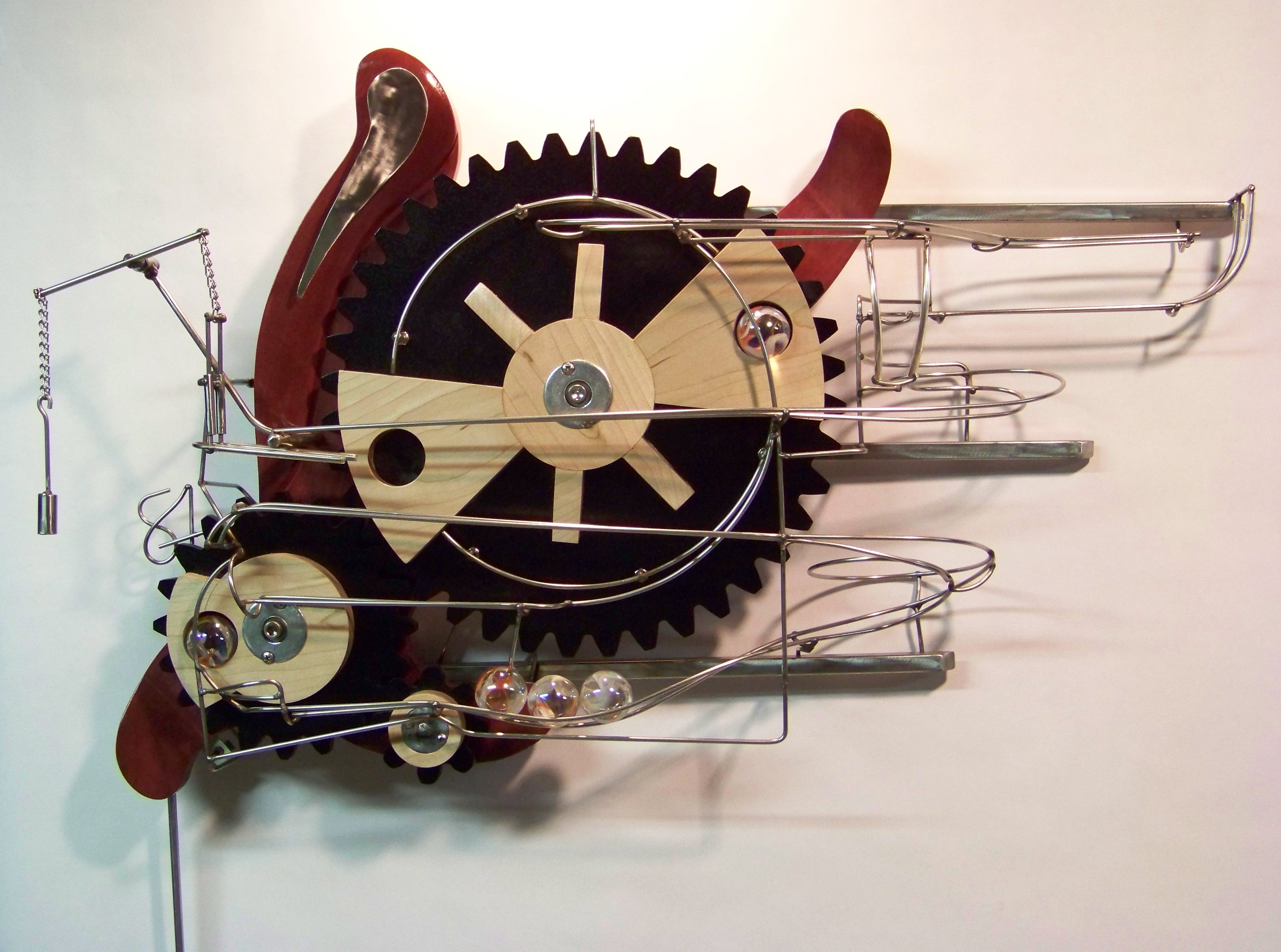

Steve Fleury used my gear-making technique to make the birch plywood gears in his sculpture #22 shown below.

He used a router table with a 1/4 inch diameter straight bit to cut the teeth. The largest gear is 13.875 inches in

diameter.

| Sculpture #22 |

|

| Steve Fleury |

Hi Steve

Mate the way you have explained

how the gear generator works and how to change the settings was just the best.

I can only say “Thank

you so very much”

Everything was just so simple and the way you explained it to me. I was playing

all day with it and my brain was hurting from the applications that I could do with the knowledge that you have passed on

to me.

You are right when you said that all of a sudden it will just click in my head and you were 100% correct.

I have printed up about 10 gears (just for fun) but the best part was when I made two gears on the table saw.

To see the gears work without any jamming of the gears it was just artwork.

I cut four spokes and stuck some

ice cream sticks on the side and then turned the compressor on and watched the gears that I had just made turn beautifully

as the air pressure turned the gears.

Again thank you so very much

Your friend,

Shane

"A simple but fantastic method of cutting gears. Well worth the investment. I was feeling a bit daunted by trying

to make wooden gear clocks again. But your method reduces the cutting time by 80%. A lot of people will be getting presents

and house warming gifts. Thank you."

Steve,

Thank

you for your email. I did get everything I needed. I am an amateur machinist and been at it for 38 years.

My calling is that of a Pastor but I make metal chips in my machine shop bus (66 passenger full of machine tools). I

also do woodworking but put myself in the wood butchery class there. I've made many metal spur gears and always

wanted to cut helical gears but that takes a universal table on your horiz. mill or a very exotic attachment that costs more

than my mill! However, your method of cutting helicals in wood will be just as thrilling to do and for making toys for

the grandkids it will be a winner. You've probably been told you're a genius before, well let me pile on as

well! Thanks for making this information available at a very reasonable price. May you prosper as your soul prospers!

Mike Fendley, Stratford, Iowa

Camp Lejeune, North Carolina. I got my

degree in physics and I love the engineering behind the gears, you can bet I will be finding a huge number of uses

for them, both for decorating (wood blinds, etc) and for functionality (I'm thinking windmill and other power generating

applications. Sky's the limit! Wonderful achievement, thank you! Jared

|